Are Steel Caster Wheels Better for Industrial Use?

In the world of industrial operations, efficiency, safety, and durability are paramount. One of the often-overlooked components that significantly contribute to these factors is the caster wheel. Caster wheels are essential in material handling, allowing heavy machinery, carts, and equipment to move smoothly and securely. Among the various types available, steel caster wheels are frequently used in demanding environments. This article explores whether steel caster wheels are better for industrial use, analyzing their advantages, limitations, and suitable applications.

Understanding Steel Caster Wheels

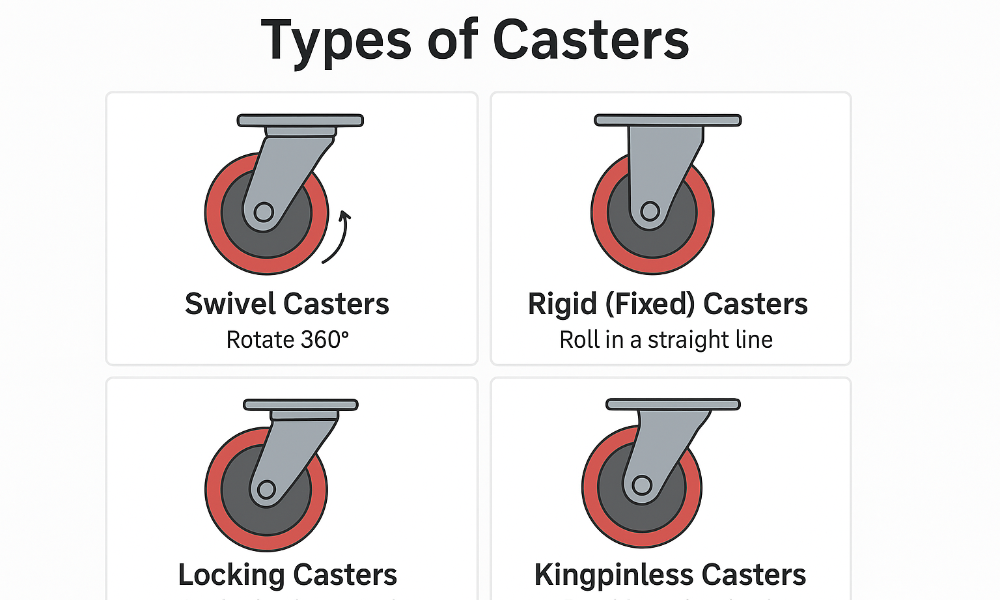

Steel caster wheels are made from high-grade carbon or stainless steel and are designed to withstand extreme weights, abrasive surfaces, and high temperatures. They come in various configurations, such as swivel and rigid types, and can be equipped with or without brakes. These wheels are commonly found in factories, automotive plants, warehouses, and foundries—anywhere that demands consistent performance under pressure.

Key Advantages of Steel Caster Wheels

-

Superior Load Capacity

One of the most compelling advantages of steel caster wheels is their ability to handle very heavy loads. Compared to plastic, rubber, or even polyurethane casters, steel wheels can support significantly higher weight capacities without deforming. This makes them ideal for transporting heavy machinery, storage racks, and industrial equipment.

-

High Durability

Steel is known for its strength and resistance to wear and tear. In high-usage environments where casters are exposed to constant friction, impact, and stress, steel wheels perform reliably. They do not chip or crack easily, and they can last several years with minimal maintenance.

-

Heat and Chemical Resistance

Steel caster wheels are highly resistant to heat, making them suitable for environments where other materials would melt, deform, or emit fumes. Additionally, stainless steel variants resist corrosion and chemical damage, which is critical in facilities involving chemical exposure or washdowns.

-

Minimal Rolling Resistance

Due to their hard surface, steel wheels provide low rolling resistance. This means they require less force to push or pull, especially on smooth concrete floors. This can improve operational efficiency and reduce worker fatigue.

Potential Disadvantages of Steel Caster Wheels

-

Noise Levels

One downside of steel caster wheels is the noise they produce during operation. On hard surfaces, the metal-to-floor contact can generate significant noise, which might not be acceptable in noise-sensitive environments such as laboratories or hospitals.

-

Floor Damage

Steel wheels can damage delicate floors over time. They may scratch, dent, or wear down surfaces such as wood, tile, or coated concrete. Therefore, floor type must be considered before choosing steel casters.

-

Higher Initial Cost

Although they offer long-term value, steel caster wheels typically have a higher upfront cost compared to plastic or rubber alternatives. However, this cost is often offset by reduced maintenance and replacement expenses.

Best Industrial Applications for Steel Caster Wheels

-

Manufacturing and Fabrication Facilities

In these environments, equipment often exceeds hundreds or thousands of pounds. Steel caster wheels are the only viable solution for reliable and safe transportation of such heavy loads.

-

Automotive Plants

Steel wheels withstand oils, solvents, and metal shavings commonly found in automotive settings. Their high temperature resistance is also beneficial near welding stations or heat-generating machinery.

-

Food Processing and Pharmaceuticals

Stainless steel caster wheels are ideal in these industries because of their ability to resist corrosion and handle frequent cleaning with harsh chemicals.

-

Foundries and Steel Mills

Where extreme heat and abrasive materials are present, only steel caster wheels can provide the required durability and performance.

Comparison with Other Caster Wheel Materials

To better understand the value of steel caster wheels, it is helpful to compare them with other common materials:

|

Material |

Load Capacity | Noise Level | Floor Protection |

Heat Resistance |

Typical Use |

| Steel | ★★★★★ | ★☆☆☆☆ | ☆☆☆☆☆ | ★★★★★ | Heavy-duty, heat/chemical exposure |

| Polyurethane | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★☆☆ | General industry, quieter floors |

| Rubber | ★★☆☆☆ | ★★★★★ | ★★★★★ | ★☆☆☆☆ | Office, light carts, hospitals |

| Nylon | ★★★☆☆ | ★★★☆☆ | ★★☆☆☆ | ★★☆☆☆ | Mid-weight, dry environments |

Steel caster wheels outperform all these options in terms of load capacity, durability, and resistance to heat and chemicals, although they may require surface protection and noise mitigation strategies.

With TARGET Casters, you don’t have to guess. Our sales engineers help you choose the ideal material based on your exact application, environment, and budget.

Maintenance and Safety Considerations

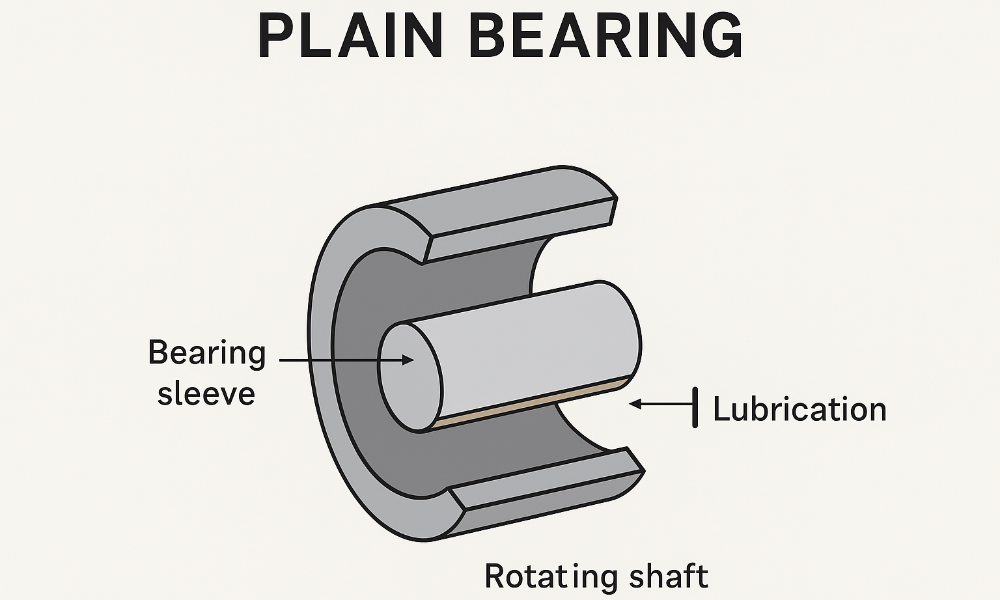

While steel caster wheels are low maintenance, periodic inspections are still necessary. Regular checks for wear on bearings, tightness of bolts, and lubrication will ensure optimal performance and longevity. Additionally, installing shock-absorbing mounts or using floor protection mats can help mitigate vibration and noise issues.

Whether you need a stock solution or a fully custom-built caster, TARGET Casters delivers fast lead times, competitive pricing, and expert support every step of the way.

Customization Options

Many manufacturers offer customization for steel caster wheels, including:

- Braking mechanisms (side brake, top lock brake)

- Different finishes (zinc-plated, chrome, or stainless steel)

- Sealed bearings for high-moisture environments

- Spring-loaded shock absorption

These options allow companies to tailor caster wheels to their specific operational needs, enhancing performance and safety.

Conclusion

Steel caster wheels are a top choice for industrial use due to their exceptional strength, durability, and resistance to heat and chemicals. While they may not be suitable for every environment—especially those requiring quiet or floor-safe movement—their advantages far outweigh their limitations in most heavy-duty applications. For facilities that prioritize load capacity, longevity, and consistent performance, steel caster wheels are not just better—they are often essential. Choosing the right caster wheel ultimately depends on your specific operational requirements, but in the industrial realm, steel remains a trusted and reliable material.

For mission-critical performance, trust TARGET Casters—the industrial caster experts that businesses across the globe rely on. Browse our steel caster collection today or speak with a product specialist to find the perfect match for your application.