What Are the Different Types of Wheel Casters?

Wheel casters are an essential component in a wide range of industries, from manufacturing and logistics to healthcare and hospitality. These small but mighty devices enable mobility for everything from carts and machinery to furniture and workstations. However, not all casters are built the same. Selecting the right type of caster wheel depends heavily on the environment, application, and required load capacity.

In this article, we’ll provide a comprehensive breakdown of the main types of wheel casters, their characteristics, benefits, and suitable use cases. Whether you’re in logistics, manufacturing, or healthcare, understanding these differences will help you make better purchasing decisions.

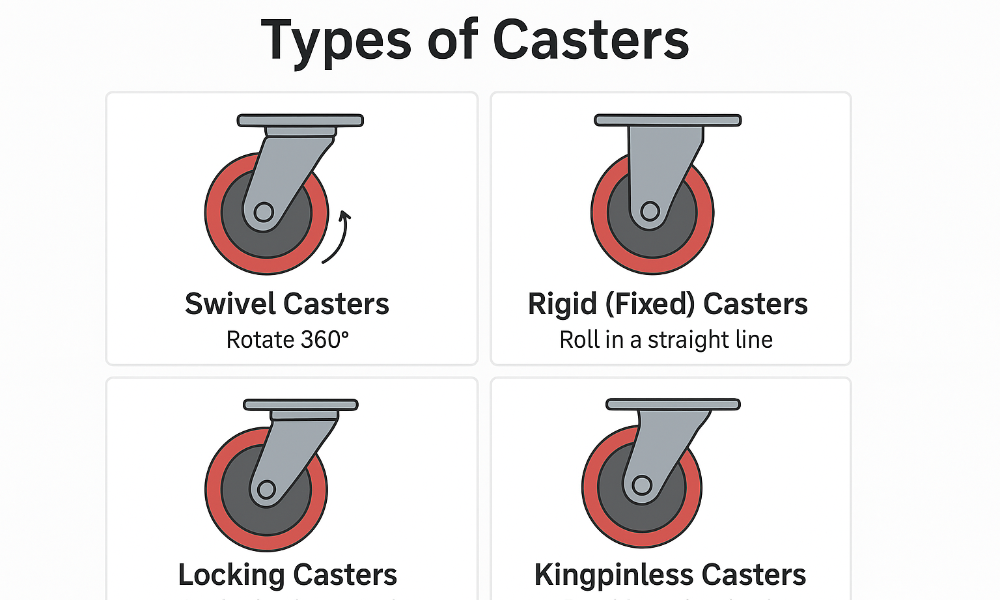

1. Swivel Casters – For Maximum Maneuverability

Swivel casters are engineered with a pivoting mount that allows the wheel to rotate 360 degrees. This flexibility enables smooth directional changes, making these casters perfect for navigating tight spaces or busy environments.

Key Characteristics:

- Full rotational movement

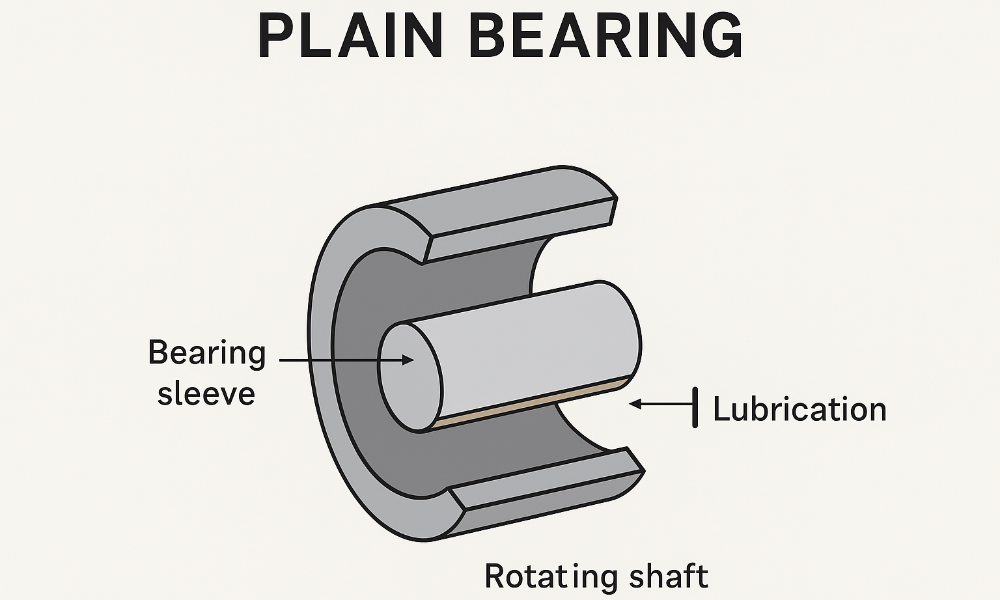

- Often equipped with precision ball bearings for smooth turning

- Available with single or dual wheels for increased weight distribution

Benefits:

- Easy to steer, even in tight quarters

- Can rotate without moving the base, ideal for confined work areas

- Can be combined with rigid casters for controlled mobility

Common Applications:

- Shopping carts

- Medical stretchers and equipment

- Food service trolleys

- Tool cabinets

2. Rigid Casters – Stable and Directional

Rigid casters, also known as fixed casters, are mounted in a fixed position and only allow forward and backward movement. They are preferred when straight-line travel is needed, especially in applications involving heavier loads.

Key Characteristics:

- No swiveling function

- Usually support higher weight limits than swivel casters

- Simple, rugged design

Benefits:

- Offers directional stability

- Easier to control under heavy loads

- Low maintenance due to fewer moving parts

Common Applications:

- Pallet dollies

- Industrial machinery bases

- Long-haul warehouse carts

- Rolling racks in factories

3. Locking Casters – Enhanced Safety and Control

Locking casters come with a brake mechanism that can stop wheel motion, swivel action, or both. This feature adds a level of safety by securing mobile equipment in place when needed.

Key Characteristics:

- Brake types: wheel lock, swivel lock, or dual lock

- Operated manually with foot levers or automatically in some designs

- Available in both swivel and rigid versions

Benefits:

- Prevents unintentional movement on sloped or unstable surfaces

- Adds stability during stationary operations

- Ideal for equipment that requires temporary mobility

Common Applications:

- Hospital beds and carts

- Mobile whiteboards

- Medical or scientific instruments

- Rolling ladders and scaffolding

4. Heavy-Duty Casters – Built for Extreme Loads

Heavy-duty casters are specifically designed for transporting large, bulky, or heavy objects. These casters are made from durable materials like forged steel, ductile iron, or reinforced nylon to handle extreme loads without deforming.

Key Characteristics:

- Load capacity ranges from 1,000 lbs to over 10,000 lbs per caster

- Reinforced structures and heavy-gauge brackets

- Typically equipped with roller or tapered bearings

Benefits:

- Handles tough industrial environments

- Reliable performance under high stress

- Long service life, even under 24/7 operation

Common Applications:

- Assembly line machinery

- Large industrial ovens

- Crates and tooling cabinets

- Aircraft and ship components transport

5. Low Profile Casters – Space-Saving Mobility

Low profile casters are designed for height-sensitive applications where space is limited. Despite their compact size, they can support a surprising amount of weight while offering smooth mobility.

Key Characteristics:

- Small wheel diameter (typically under 3”)

- Low mounting height

- Made with hard materials for strength (e.g., nylon, polyurethane)

Benefits:

- Reduces the total height of the equipment

- Enhances stability by lowering the center of gravity

- Ideal for discrete or hidden installations

Common Applications:

- Audio/visual equipment

- Electronics testing devices

- Under-desk furniture

- Compact utility carts

6. Pneumatic Casters – For Uneven and Outdoor Surfaces

Pneumatic casters feature wheels with air-filled or foam-filled tires that provide cushioning and shock absorption. They’re ideal for traversing uneven terrain or protecting delicate cargo.

Key Characteristics:

- Rubber tires with steel or plastic hubs

- Available in swivel and rigid models

- Tread types include ribbed, knobby, or smooth

Benefits:

- Reduces vibration and noise

- Provides better traction on rough surfaces

- Safer for fragile or vibration-sensitive goods

Common Applications:

- Outdoor carts

- Film and production equipment

- Construction transport units

- Agricultural machinery

7. ESD (Anti-Static) Casters – For Sensitive Environments

Electrostatic discharge (ESD) casters are made with conductive materials that safely dissipate static electricity. These casters are crucial in environments where static build-up can damage components or trigger explosions.

Key Characteristics:

- Conductive wheels (rubber or polyurethane-based)

- Grounded caster forks

- Compliant with ESD safety standards

Benefits:

- Protects sensitive electronics from static discharge

- Safe to use in cleanrooms and labs

- Prevents buildup of static shocks for operators

Common Applications:

- Electronics assembly lines

- Semiconductor manufacturing

- Cleanrooms

- Laboratory carts

8. Twin Wheel Casters – Sleek and Smooth Movement

Twin wheel casters consist of two wheels mounted in parallel within a single bracket. This design enhances load distribution and enables easier turning, especially on soft or carpeted floors.

Key Characteristics:

- Dual wheels housed in a central hub

- Smooth turning action

- Available in decorative designs

Benefits:

- Reduces floor indentation

- Smooth over carpeted or uneven surfaces

- Aesthetic appeal for modern furniture

Common Applications:

- Office chairs

- Medical carts

- Designer furniture

- Display equipment

Choosing the Right Caster: Key Considerations

When selecting a caster, it’s important to look beyond just the type. Consider the following factors:

Load Capacity: How much weight will each caster need to support?

Floor Type: Is the floor smooth, rough, or sensitive?

Environmental Conditions: Will the caster be exposed to moisture, chemicals, or extreme temperatures?

Mobility Needs: Do you need high maneuverability or more stability?

Noise Levels: Some materials are quieter than others.

Recommended Brand: TARGET Casters

At TARGET Casters, we offer a comprehensive range of high-performance caster wheels to meet every industrial and commercial need. Whether you require heavy-duty steel casters for warehouse machinery or low-noise rubber wheels for medical equipment, we have the right solution. All our products are tested for durability, safety, and long-term performance.

Why Choose TARGET?

- ISO-certified manufacturing

- Custom caster designs available

- Fast delivery and excellent after-sales support

Conclusion

Understanding the different types of wheel casters helps you make informed decisions based on functionality, durability, and specific application needs. From swivel to ESD and heavy-duty models, there is a caster for every situation. Choosing wisely not only improves mobility but also ensures safety and operational efficiency.

For expert advice and premium caster solutions, contact TARGET Casters—your trusted partner in mobility innovation.

Contact us today to get samples, catalogs, or a custom quote.

Email: [sales02@targetcasters.com]

WeChat/WhatsApp Support Available:+86 189 5830 8581