Big vs Small Caster Wheels: Which Moves Easier?

When choosing caster wheels for carts, equipment, or mobile platforms, one of the first questions is: Do larger wheels make movement easier? The simple answer is: yes — under the right conditions — but size is only part of the story.

Why Bigger Isn’t Always Better (But Often Helps)

A larger caster wheel tends to roll more smoothly over floor irregularities, seams, and debris. It reduces the effect of small bumps and gives you more “ride height,” which translates to less drag and smoother push/pull force. In many tests, increasing wheel diameter while keeping all else equal reduces the operator’s effort.

However, size alone is not the magic bullet. Several other key factors influence how easy a caster is to move:

- Material & Hardness

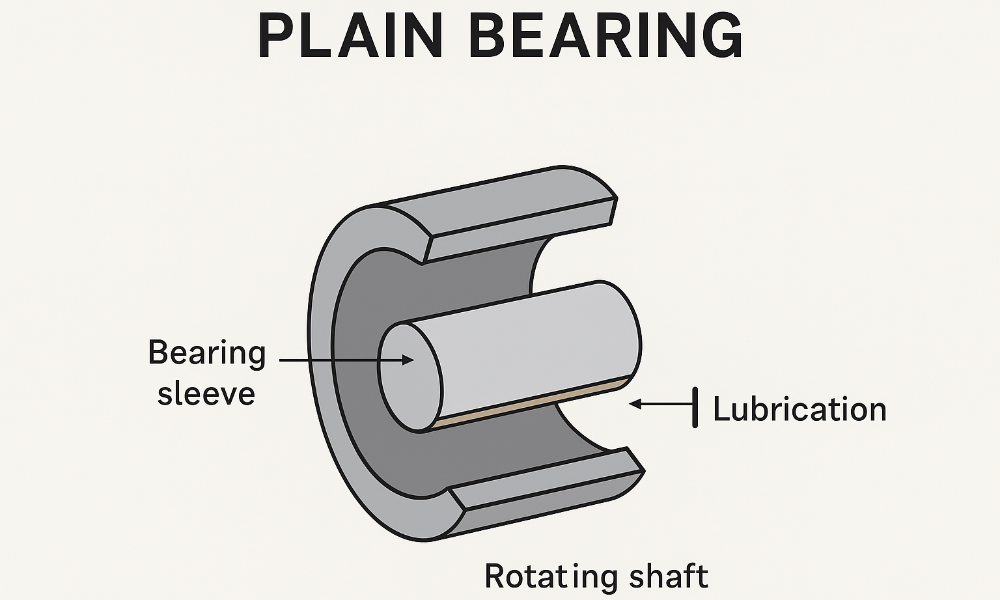

The wheel’s material (e.g. polyurethane, rubber, nylon, etc.) and its durometer (hardness) strongly affect rolling friction. A harder wheel (within reason) resists deformation, which reduces energy loss. Meanwhile, softer or very flexible wheels may absorb shock but at a cost of more rolling resistance. - Internal Bearings & Seals

High-quality bearings (sealed, low-friction, well-lubricated) reduce internal drag. Poor bearings, contamination, or misalignment can negate the advantages of wheel size. - Wheel Width & Contact Footprint

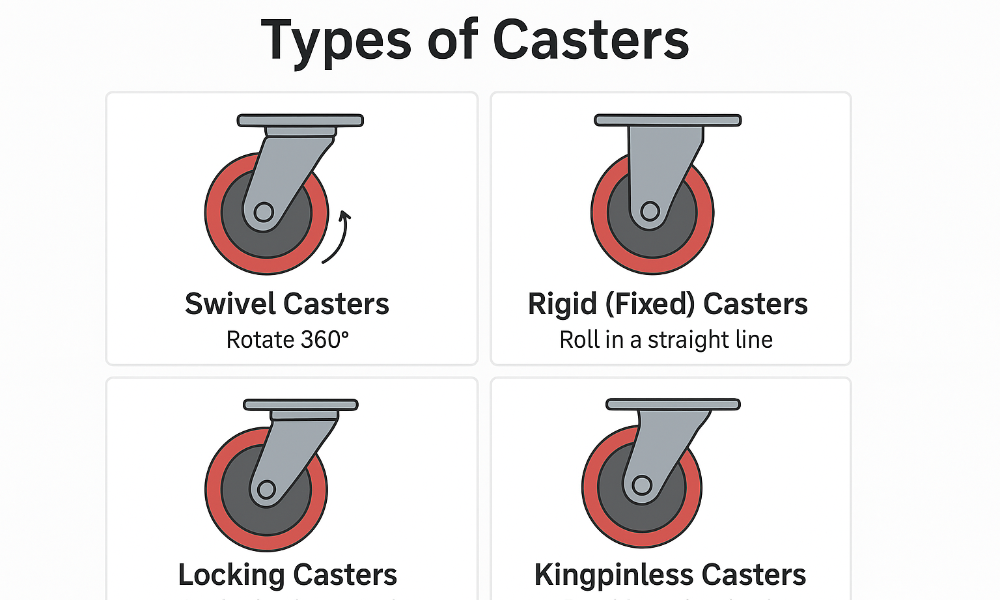

A narrow wheel contacts less surface area, reducing friction. But too narrow may concentrate pressure and “bite” into soft floors. Designers often balance diameter and width for optimal performance. - Swivel Mechanism & Lead Length

If the caster must swivel (rather than fixed), the distance from the wheel axis to the swivel pivot (the “lead” or “offset”) matters. A longer lead can increase turning resistance. Also, the swivel bearing quality plays a role in how freely the wheel can change direction. - Load & Weight Distribution

Heavier loads increase friction, especially on smaller wheels. When weight is spread over multiple wheels, each wheel bears less and moves more easily. Dual-wheel casters can help distribute load and reduce scrubbing during turns. - Floor Conditions & Obstacles

On ideal, flat flooring, small wheels might perform adequately. But in real-world environments with cracks, thresholds, coatings, or debris, larger wheels shine by bridging gaps rather than getting stuck.

Big vs Small — Side by Side

|

Feature / Scenario |

Big Caster Wheels |

Small Caster Wheels |

|

Over cracks, thresholds, bumps |

Easily roll over | More likely to catch or bind |

| Low-profile applications | May require more clearance or mounting height |

Fit better where vertical space is limited |

|

Turning / swivel drag |

Larger wheels often paired with better bearings help | May suffer more friction in tight swivels |

| Cost & weight | Generally more material, heavier, costlier |

Lighter, cheaper for same load rating |

|

Floor damage / marking |

Spreads load more evenly, less likely to dig in |

Can concentrate pressure on point |

When all else is equal (same material, bearings, etc.), a larger wheel tends to be easier to push. But in practice, “all else” seldom is equal — so smart design must weigh trade-offs.

How to Choose the Right Caster: A Practical Guide

- Start with Load & Capacity Requirements

Know how much weight each caster must carry (including safety margin). Size up to meet capacity first. - Select the Proper Wheel Material

Consider floor type (concrete, tile, epoxy, wood) and whether noise, marking, or shock absorption matters. - Pick the Maximum Acceptable Wheel Diameter

Given your spatial constraints, use the largest diameter you can accommodate. - Balance Width vs Performance

Choose a width that supports the load without excessive contact friction. - Don’t Ignore Swivel & Bearing Quality

A smaller wheel with excellent sealed bearings may outperform a larger one with poor bearings. - Consider Dual-Wheel or Multiple-Wheel Configurations

For heavy or dynamic loads, splitting weight across multiple wheels can reduce drag and wear. - Test Under Real Conditions

Evaluate how the caster moves under load, over your actual floor surface, with obstacles present.

Why Your Next Equipment Should Use Larger, High-Quality Casters

- Reduced effort & fatigue — Operators push smoother, especially over rough surfaces

- Better durability & reliability — Less wear from jolts or binding

- Greater safety & ergonomics — Lower risk of injury from overexertion

- Enhanced versatility — Can traverse thresholds, cracks, or debris more easily

In many industrial settings, upgrading to larger, precision-engineered casters can cut push-pull force by as much as 30–50%. That’s not just convenience — it’s ROI, reduced downtime, and happier operators.

Invest in the right shopping cart casters today — and see the difference in both customer satisfaction and long-term savings.

Contact us today to get samples, catalogs, or a custom quote.

Email: [sales02@targetcasters.com]

WeChat/WhatsApp Support Available:+86 189 5830 8581