Custom Casters for High Temperature Applications

When equipment is exposed to heat, standard caster wheels quickly reach their limits. Rubber becomes brittle, plastics deform, and lubrication fails — resulting in downtime, higher replacement costs, and safety concerns. For industries that operate in ovens, autoclaves, foundries, or food processing lines, the solution is clear: custom casters designed for high temperature applications.

TARGET CASTERS specializes in manufacturing heat resistant caster wheels that not only withstand extreme conditions but also enhance efficiency and reliability. By combining advanced materials, precision engineering, and customization options, we deliver caster solutions that keep your business moving even in the harshest environments.

Want more details about TARGET CASTERS?Dive into this website:https://www.targetcasters.com/about-us/

Why Choose Custom Casters Over Standard Wheels?

Standard caster wheels are built for general use — not for ovens, furnaces, or high-heat processing facilities. Here’s why custom casters make the difference:

- Heat Resistance: Standard rubber casters typically fail above 80°C (176°F). Our high temperature casters can perform continuously at 250°C (482°F) and handle short-term exposure up to 300°C (572°F), depending on material selection.

- Durability Under Stress: Heat weakens conventional wheels, causing cracks and deformation. With custom casters, materials like forged steel, phenolic resin, or high-temp polyurethane are selected specifically to resist heat and maintain structural integrity.

- Tailored to Application: Every factory, oven, or sterilization process is unique. Customization ensures you get the exact load capacity, rolling performance, and safety features you need.

What Makes Custom Casters Different?

Unlike off-the-shelf wheels, custom casters are designed and built around your exact requirements. This ensures:

- Temperature Tolerance – Wheels built from specialized materials that perform continuously at 250°C (482°F) and withstand short peaks beyond that.

- Load Adaptability – From lightweight oven racks to industrial carts carrying over 10,000 lbs, casters can be engineered to your weight requirements.

- Precision Fit – Mounting patterns, heights, and wheel sizes designed to fit your existing equipment without modification.

- Durability – Bearings, seals, and lubricants selected to resist high heat, moisture, and chemical exposure.

Key Features of Our High Temperature Casters

When you choose our custom casters, you benefit from engineered details that make a real difference in hot environments:

- Specialized Wheel Materials

Phenolic resin: Lightweight, strong, and heat-resistant up to 250°C.

Forged steel: Handles extremely heavy loads and continuous exposure to high heat.

High-temp polyurethane: Provides a balance between load-bearing strength, quiet rolling, and heat resistance.

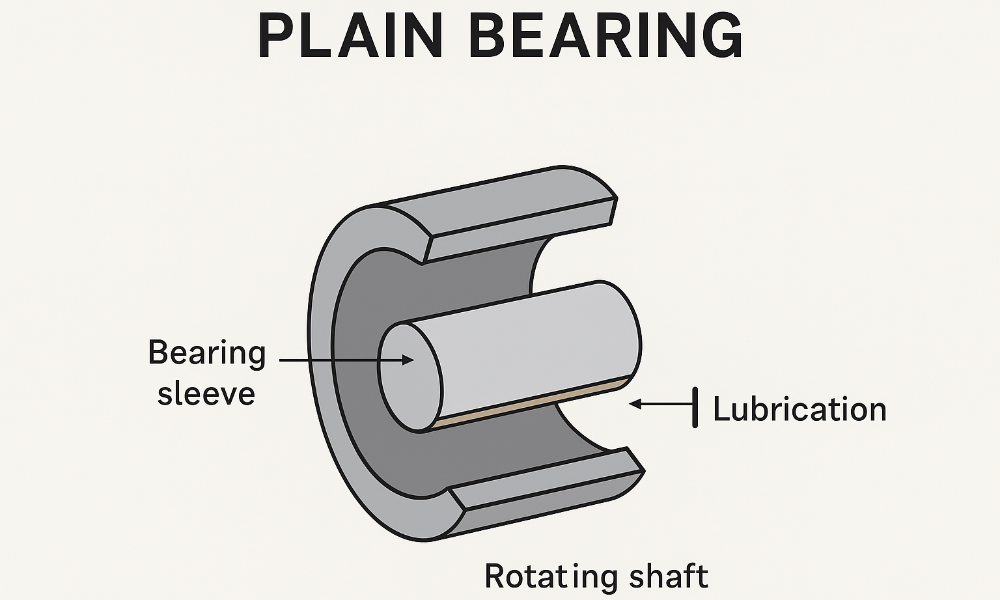

- High-Temperature Bearings & Lubrication

Precision bearings designed for smooth rolling under heat.

Heat-resistant grease ensures long-term performance without seizing.

- Protective Coatings & Frames

Stainless steel or zinc-plated frames for corrosion resistance.

Custom finishes for environments with steam, chemicals, or moisture.

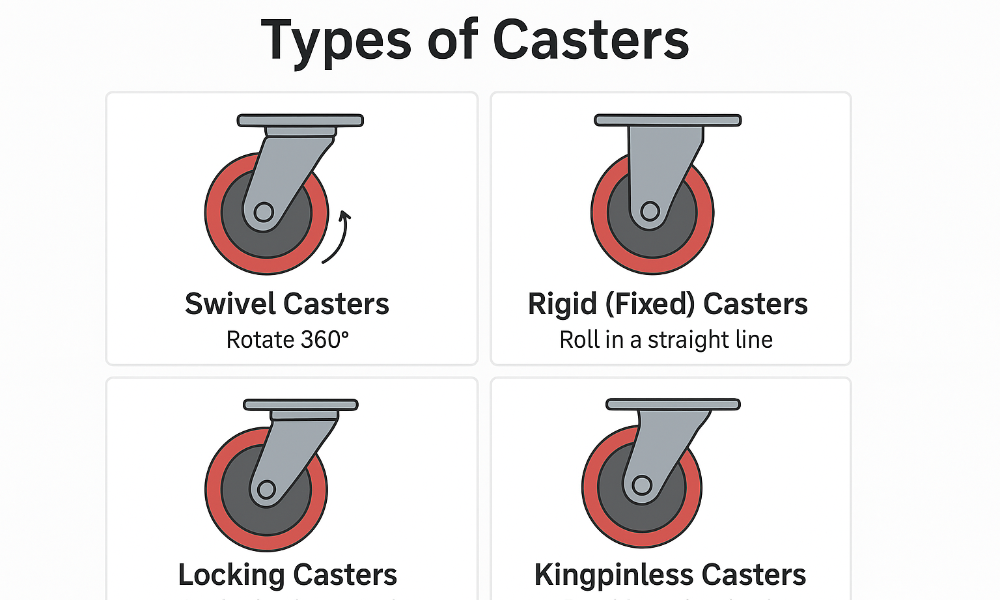

- Safety Options

Brakes to lock equipment in place.

Toe guards for worker safety.

Swivel locks for directional stability in industrial settings.

Industries That Rely on Heat Resistant Custom Casters

Our custom high temperature casters are trusted in industries where heat is part of daily operations:

- Food Processing & Bakeries: Moving trays, racks, and carts in and out of ovens.

- Autoclaves & Sterilization Chambers: Equipment that must endure both heat and steam.

- Metal Processing & Foundries: Heavy-duty carts and racks exposed to molten materials.

- Industrial Manufacturing: Drying ovens, curing systems, and other thermal processes.

- Pharmaceutical & Medical: Sterile environments requiring both heat resistance and hygiene.

Each application has its own challenges — which is why a one-size-fits-all caster simply doesn’t work.

The Customization Process

Ordering custom casters is straightforward, and our engineering team supports you at every stage:

- Define Your Needs: Tell us about your operating temperature, load requirements, and environment.

- Material Selection: Our experts recommend the best wheel materials, bearings, and frame coatings for your conditions.

- Design & CAD Modeling: We provide 3D models and detailed drawings for review.

- Prototyping (if required): For complex applications, prototypes are tested before full production.

- Production & Delivery: With all processes in-house, we ensure fast turnaround without sacrificing quality.

Materials for High Temperature Custom Casters

Selecting the right material is critical to performance:

- Phenolic Resin Wheels – Lightweight, economical, and resistant to continuous high heat, ideal for bakery racks and food ovens.

- Forged Steel Wheels – Extremely durable, capable of withstanding both heat and heavy loads; commonly used in foundries and steel plants.

- High-Temperature Polyurethane Wheels – A balance of heat resistance and quiet, cushioned movement; perfect for environments where noise reduction matters.

- Stainless Steel Components – Used in caster frames, bearings, and fasteners for sanitary or corrosive environments like food processing or chemical plants.

Why Work With Us as Your Caster Wheels Manufacturer?

In-House Manufacturing – We cut, weld, machine, and assemble everything under one roof.

Faster Lead Times – Many modifications are completed without extending delivery schedules.

Expert Engineering Support – Our team collaborates with you to match performance, safety, and cost requirements.

Proven Track Record – Trusted by industries worldwide for reliable caster solutions.

Cost Factors for Custom Casters

While custom casters are tailored solutions, they don’t always mean higher costs. Factors affecting price include:

- Wheel material (phenolic vs. steel vs. polyurethane)

- Load capacity requirements

- Bearing selection (standard vs. high-performance)

- Optional features such as brakes, guards, or locks

- Stainless steel or specialized finishes

In many cases, the added cost of customization is offset by longer caster life, reduced downtime, and improved workplace safety.

Get Your Custom High Temperature Casters Today

Contact us today to get samples, catalogs, or a custom quote.

Email: [sales02@targetcasters.com]

WeChat/WhatsApp Support Available:+86 189 5830 8581