Caster Wheels: Types, Uses, and Control

Caster wheels are essential components in various industries and daily life applications, providing smooth and efficient movement for carts, furniture, medical equipment, and more. Whether you’re setting up a warehouse or assembling a workbench, understanding the different types of caster wheels, when to use them, and how to stop them from rolling can help you choose the right solution for your needs.

What Are the Common Types of Caster Wheels?

Caster wheels come in a wide range of materials and designs, each suited for specific environments and loads. Here are some of the most common types:

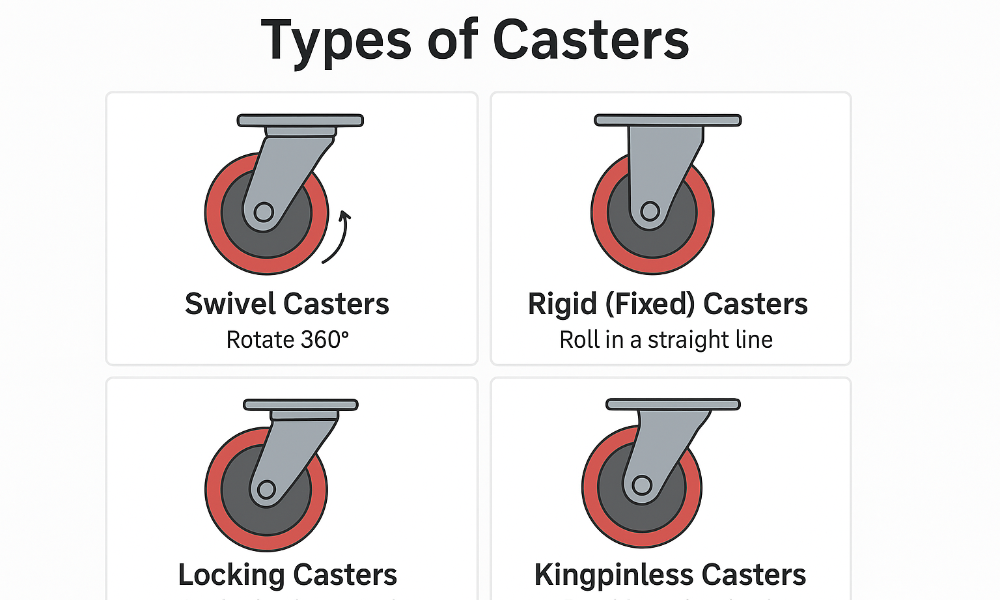

These wheels can rotate 360 degrees, allowing for greater maneuverability. They are ideal for equipment that needs to change direction frequently.

Unlike swivel casters, rigid casters move in a straight line. They are typically used alongside swivel casters for stable forward movement.

These casters include a brake mechanism that locks the wheel and sometimes the swivel simultaneously, providing stability when stationary.

-

Pneumatic Casters

Made with air-filled tires, pneumatic casters are ideal for rough or uneven surfaces. They offer shock absorption and quiet movement.

Durable and wear-resistant, PU casters are suitable for heavy loads and provide good floor protection. They are often used in industrial and commercial settings.

Known for quiet and smooth operation, rubber casters are great for light-duty use on indoor floors like tile or wood.

Part of the RUBBER casters provided by TARGET Casters |

||||||||

Part name |

TARGET Number |

Material |

Wheel Diameter |

Wheel Tread Width |

Overall Height |

Installation information |

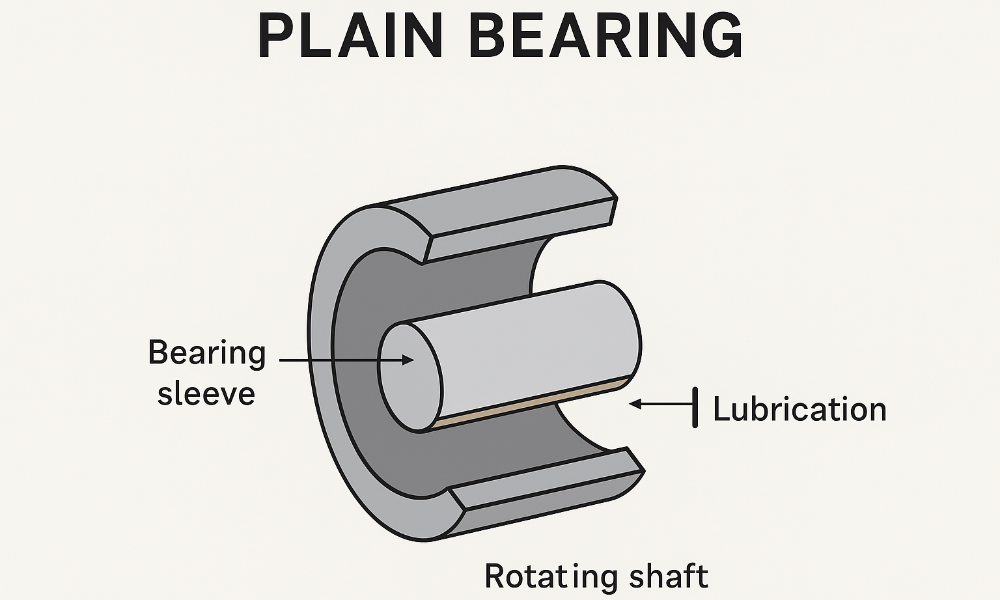

Bearing |

Load Capacity |

| 3″ Light Duty 304 Stainless Steel Rubber Threaded Stem Swivel Caster | TC-RBTSA075-01 | Rubber + Stainless Steel | 3″ φ75mm |

1.25″ 32mm |

4.3″ 110mm |

Threaded Stem:3/8″-16 Stem length:1-1/8″ |

Bushing/ Dual stainless steel Precision Ball Bearings |

114kg(250lbs) |

| 5″ Rubber Warehouse Logistics Wheel | 33W RB12501 | Thread material : Rubber, 70-75° Shore A hardness

Hub Material: PP |

5″ φ125mm |

1.46″ 37mm |

5″ φ125mm |

Assembly Hole Diameter: 15mm(0.6″) |

6202 Roller bearing | 150 kg (330 lbs) |

| 5″ Rubber Grey Silent Wheel | 33W RB12502 | Thread material : Rubber, 85° Shore A hardness

Hub Material: PP |

5″ φ125mm |

1.42″ 36mm |

5″ φ125mm |

Assembly Hole Diameter: 10mm(0.4″) |

6202 Roller bearing | 100kg(220 lbs) |

| 4″ Rubber Grey Wheel | 33W RB10001 | Thread material : Rubber, 85° Shore A hardness

Hub Material: PP |

4″ φ100mm |

1.42″ 36mm |

4″ φ100mm |

Assembly Hole Diameter: 10mm(0.4″) |

6202 Roller bearing | 70 kg(154 lbs) |

| 5″ Rubber Black Silent Wheel | 33W RB12503 | Thread material : Rubber, 85° Shore A hardness

Hub Material: PP |

5″ φ125mm |

1.42″ 36mm |

5″ φ125mm |

Assembly Hole Diameter: 10mm(0.4″) |

6202 Roller bearing | 100kg(220 lbs) |

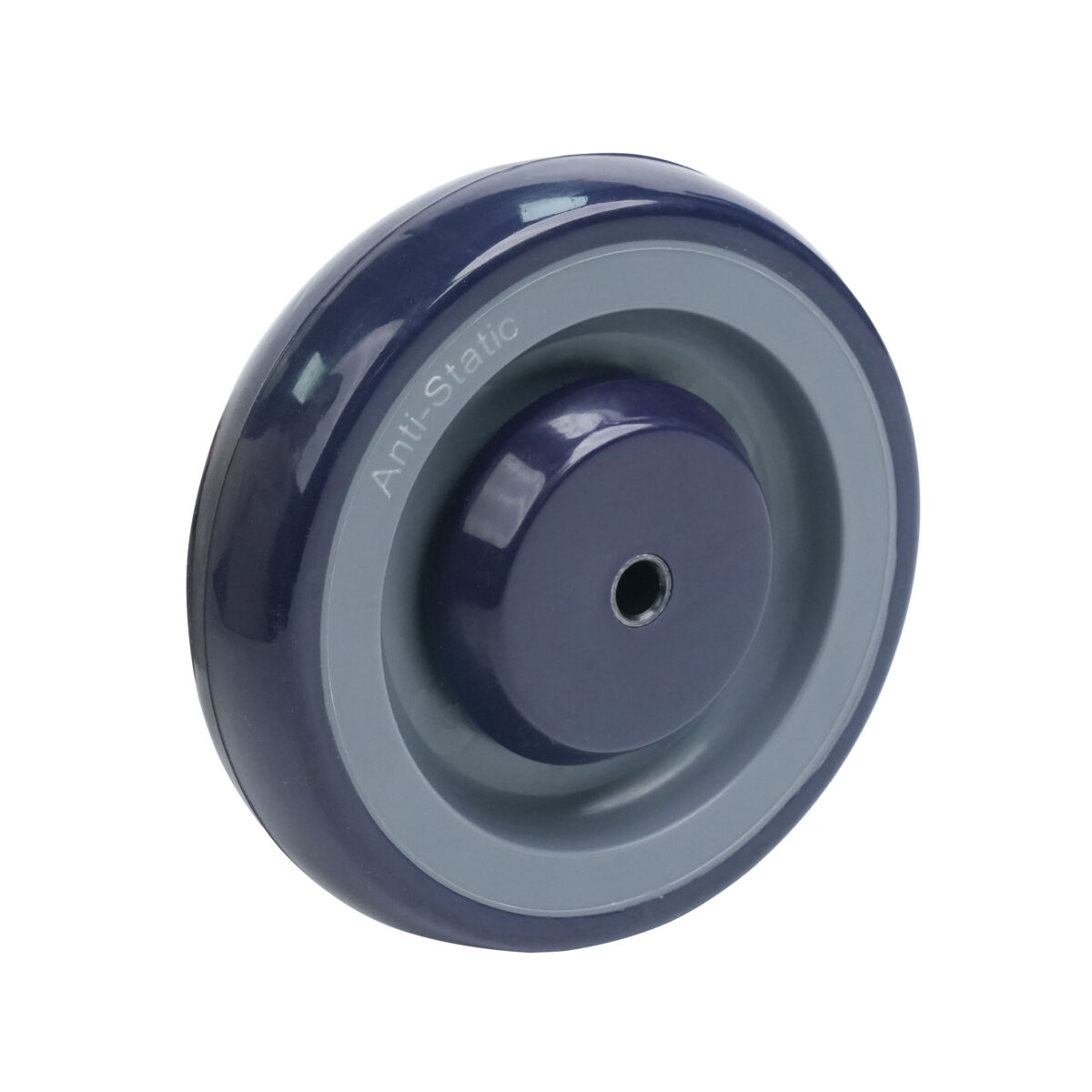

These are designed for environments where static electricity must be controlled, such as electronics manufacturing.

When Is a Caster Wheel Used?

Caster wheels are used in a wide variety of applications across industries:

- Industrial and Warehousing: For moving heavy equipment, carts, and pallets.

- Medical Equipment: Hospitals use caster wheels on beds, IV poles, and diagnostic machines for easy movement.

- Furniture: Office chairs, cabinets, and movable tables often come with casters for convenience.

- Retail: Display stands and shopping carts rely on casters for mobility.

- Food Service: Casters help move kitchen equipment and serving carts quickly and safely.

- DIY and Home Projects: Toolboxes, plant stands, and workbenches can be made mobile with caster wheels.

In general, whenever there’s a need to move something heavy or frequently repositioned, caster wheels provide a practical and efficient solution.

How to Stop Caster Wheels from Rolling

While mobility is the main benefit of caster wheels, sometimes it’s necessary to keep them stationary. Here are some effective methods:

- Use Locking Casters

Choose casters with integrated locks that can be engaged with a foot pedal. Some lock only the wheel, while others lock both the wheel and the swivel mechanism. - Wheel Chocks or Stoppers

Place physical stoppers in front of the wheels. This is a simple solution for carts and trolleys without built-in brakes. - Caster Cups or Pads

These are rubber or plastic accessories placed under caster wheels to prevent rolling and protect flooring. - Friction Tape or Rubber Mats

Increase traction under the wheels using rubber mats or tape to reduce movement on slick surfaces. - Temporary Removal

If mobility is no longer needed, consider replacing caster wheels with fixed legs or glides.

Conclusion

Caster wheels are versatile tools that offer convenience and efficiency in countless applications. By understanding the different types, knowing when to use them, and applying proper techniques to stop them from rolling when needed, you can maximize safety and performance in any environment. Whether you’re outfitting a factory or rearranging a home office, the right caster wheel solution makes all the difference.