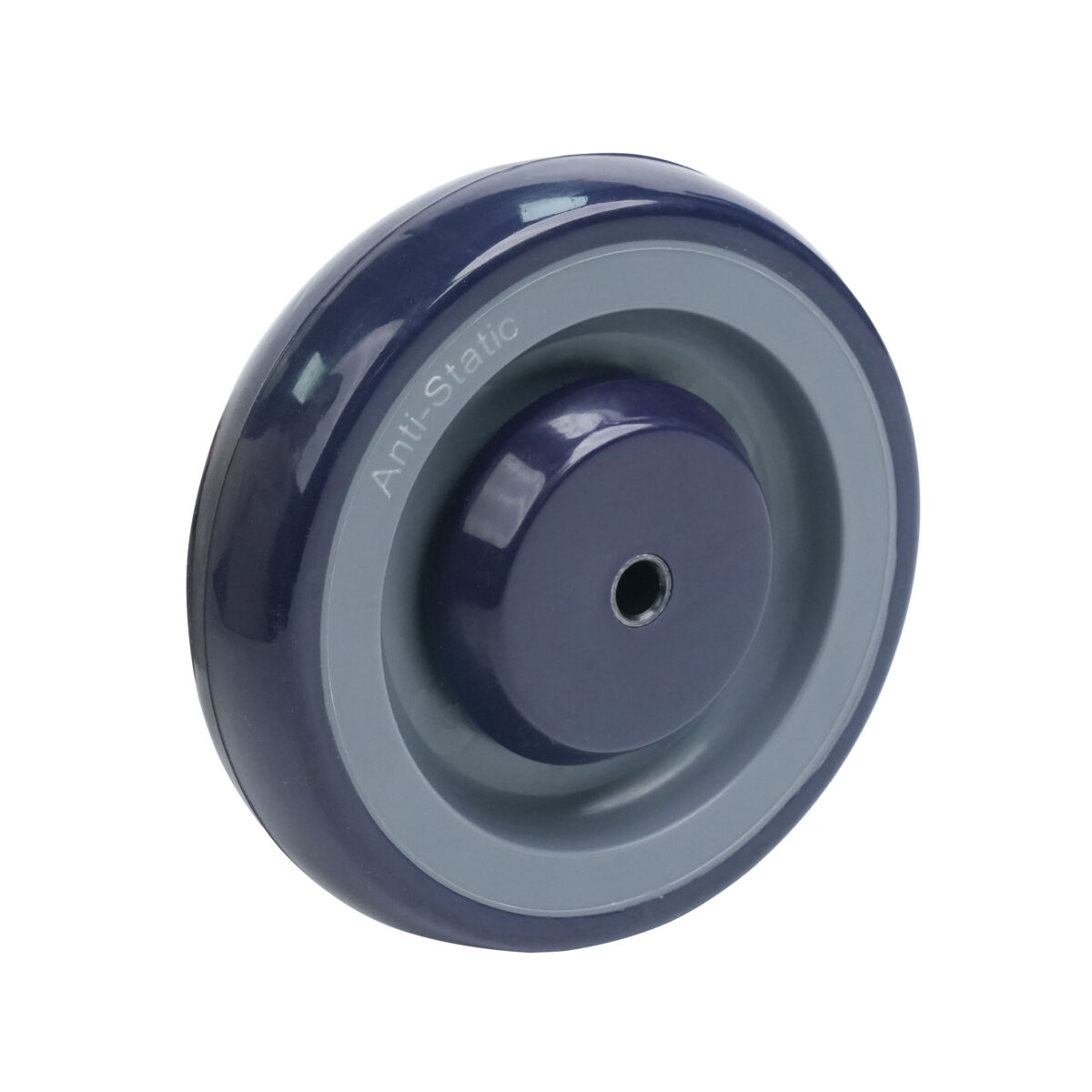

Rubber Anti-Static Wheel

In today’s fast-paced industrial world, safety, efficiency, and precision are non-negotiable. One often-overlooked yet critical component that ensures smooth operations across various industries is the rubber anti-static wheel. These specialized caster wheels are designed to prevent the buildup and discharge of static electricity—a silent threat in sensitive environments such as electronics manufacturing, medical facilities, and chemical plants.

What Are Rubber Anti-Static Wheels?

Rubber anti-static wheels are caster wheels made from specially formulated rubber materials that help dissipate static electricity. Unlike traditional rubber wheels, which can accumulate an electric charge through friction with the ground, anti-static rubber wheels contain additives that either prevent this charge from building or safely discharge it to the ground.

These wheels typically have the following features:

- Surface resistivity of 10⁵–10⁹ ohms (dissipative range)

- Good shock absorption

- Smooth and quiet rolling performance

- Non-marking tread

- Optional conductive hubs or grounding strips

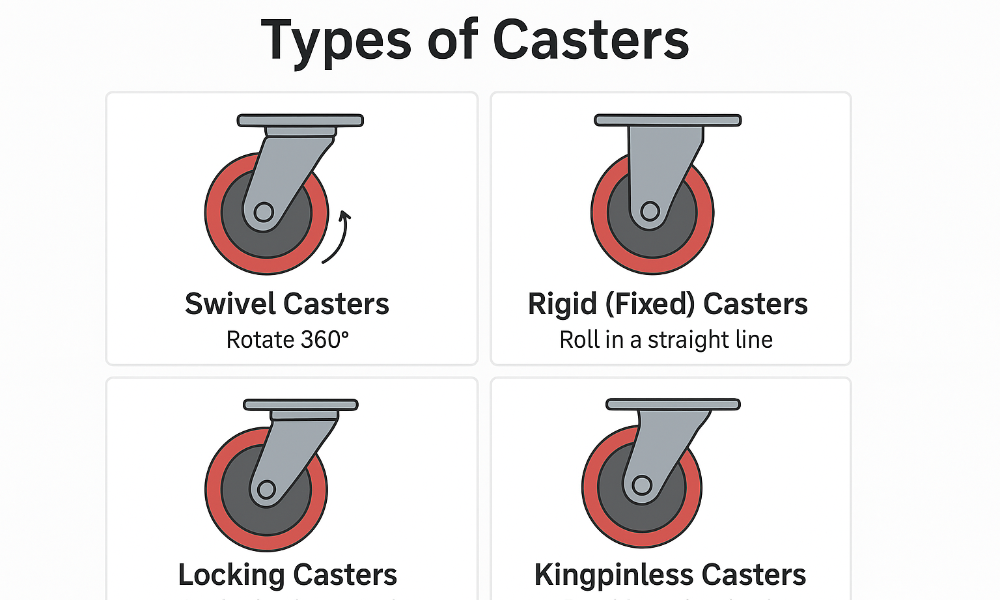

Rubber anti-static wheels are widely used in:

- Electronics assembly lines

- Cleanrooms

- Explosive-handling zones

- Hospital carts and equipment

- Laboratories

What Are Anti-Static Additives for Rubber?

Anti-static additives are specialized chemical compounds added to rubber formulations during manufacturing. Their primary function is to reduce or eliminate the buildup of static electricity on the rubber surface.

There are two main types:

- Internal anti-static additives – blended into the rubber compound before vulcanization. These migrate to the surface over time to provide long-term dissipation.

- External coatings – applied to the surface of the finished wheel to provide immediate anti-static properties, though often less durable.

Common examples of anti-static additives include:

- Quaternary ammonium salts

- Polyether-based surfactants

- Metallic salts or conductive fillers (like carbon black or graphite)

In the case of rubber wheels, internal additives are usually preferred because of their durability and uniform static control across the wheel’s lifetime.

How Do Anti-Static Additives for Rubber Work?

To understand how these additives work, it’s essential to know how static builds up:

When rubber wheels roll across a surface, friction causes electrons to transfer, leading to charge accumulation on the wheel. If this charge is not dissipated, it can:

- Damage sensitive electronics

- Create sparks in flammable environments

- Attract dust and contaminants

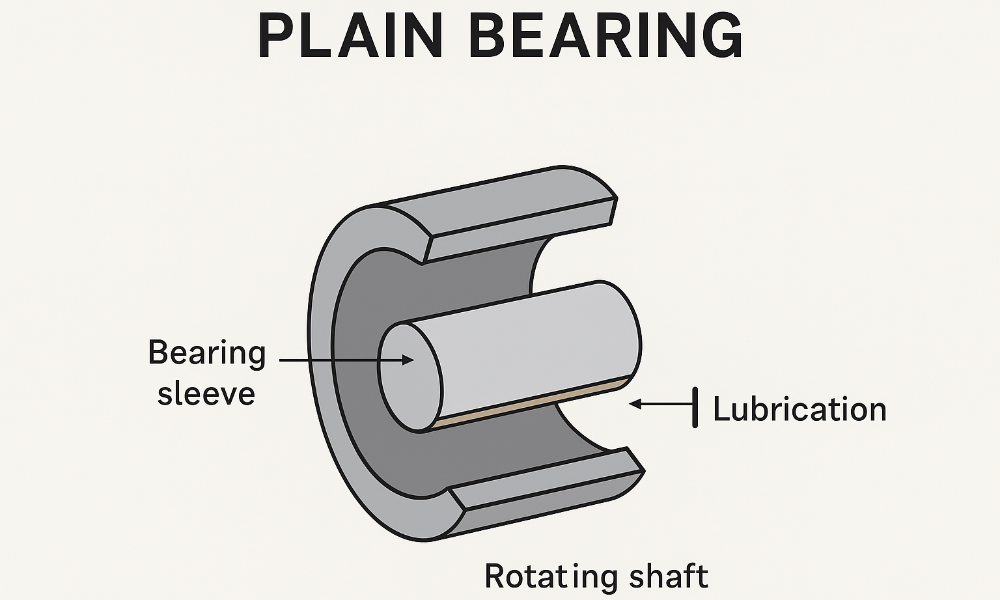

Anti-static additives function by increasing the conductivity of the rubber compound, allowing electrons to flow from the wheel to the ground or surrounding environment. This prevents dangerous static discharge (electrostatic discharge, or ESD).

There are two mechanisms at play:

- Surface conductivity: Additives create a conductive path on the rubber surface.

- Volume conductivity: Additives are dispersed throughout the rubber, allowing electricity to pass through the wheel itself.

The effectiveness depends on additive type, dosage, rubber type, and environmental factors like humidity.

The Importance of Rubber Anti-Static Wheels in Industries

Industries that rely on precision, cleanliness, or explosive safety cannot afford to ignore static electricity. Rubber anti-static wheels offer a reliable, low-maintenance solution for such environments.

Here’s why they are vital:

Industry |

Risk Without Anti-Static Wheels |

Benefit of Rubber Anti-Static Wheels |

|

Electronics Manufacturing |

ESD damaging sensitive circuits or boards | Safe discharge of static electricity |

|

Chemical Processing |

Spark-induced explosions from volatile chemicals | Minimization of ignition risk |

| Healthcare & Labs | Equipment malfunction or data corruption |

Controlled environment for medical devices |

| Cleanrooms | Static attracting dust or particles |

Maintains ISO class cleanliness |

Moreover, rubber wheels offer excellent shock absorption, making them ideal for protecting sensitive equipment during transport. Their quiet, smooth operation also improves workplace comfort and reduces noise pollution.

Conclusion: Why Choose Rubber Anti-Static Wheels?

Rubber anti-static wheels combine the elasticity and shock-absorbing features of rubber with essential static-dissipative properties. By incorporating advanced anti-static additives, manufacturers can create wheels that:

- Enhance operational safety

- Prevent costly damage

- Maintain clean and ESD-safe environments

If your business operates in sensitive environments, investing in quality rubber anti-static caster wheels is not just a precaution—it’s a necessity.

At TARGET Casters, we specialize in manufacturing high-performance anti-static rubber wheels tailored for industrial and cleanroom applications. With precision engineering and strict quality control, our wheels ensure smooth operation and optimal safety across all sectors. Contact us today for samples and custom solutions.

Contact us today to get samples, catalogs, or a custom quote.

Email: [sales02@targetcasters.com]

WeChat/WhatsApp Support Available:+86 189 5830 8581