Types of Casters & Wheel Guide

Casters and wheels are essential components in material handling, manufacturing, and industrial design. They make heavy loads mobile, increase productivity, and reduce physical strain. However, not all casters are the same — understanding their types, functions, and materials is the key to choosing the right one for your equipment.

1. What Is a Caster?

A caster is a complete assembly that includes a wheel, a bracket (also called a rig or fork), and a mounting system.

Casters can swivel for steering or remain fixed for straight-line movement. They’re used on carts, racks, platforms, machines, and even hospital equipment.

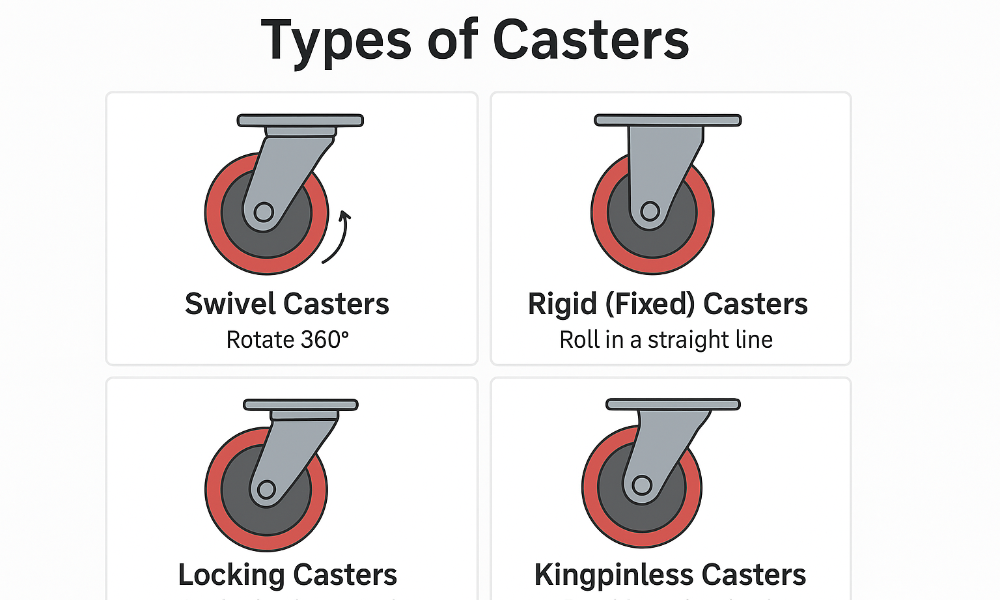

2. Main Types of Casters

(1) Swivel Casters

Swivel casters rotate 360°, allowing equipment to change direction easily. They’re ideal for tight spaces or applications where frequent turning is needed, such as warehouse carts or hospital beds.

(2) Rigid (Fixed) Casters

Rigid casters roll in a straight line and do not swivel. They’re usually paired with swivel casters to provide directional control and stability for long-distance movement.

(3) Locking Casters

These casters include a brake system that locks the wheel, the swivel, or both. They keep equipment stationary during loading or maintenance.

(4) Kingpinless Casters

Unlike traditional designs that use a center rivet (kingpin), kingpinless casters feature a raceway without a pin. This design reduces wear and resists shock — perfect for heavy-duty industrial use.

(5) Specialty Casters

- Spring-loaded casters absorb shock and protect fragile loads.

- Low-profile casters provide stability for heavy machinery with low clearance.

- Medical casters are quiet, smooth, and non-marking for hospital environments.

3. Common Mounting Styles

The way a caster attaches to equipment affects both strength and flexibility.

Mount Type |

Description |

Typical Use |

|

Top Plate |

A flat metal plate with bolt holes for secure installation. | Heavy-duty industrial carts |

| Threaded Stem | A threaded rod that screws into a socket or nut. |

Furniture and light-duty use |

|

Grip Ring Stem |

Smooth stem held by friction ring. | Office chairs and light carts |

| Bolt Hole Mount | Uses a central bolt through the caster frame. |

Medium-duty applications |

4. Wheel Materials & Their Features

The wheel is where movement meets the floor — its material determines how well the caster performs.

Wheel Material |

Advantages |

Best For |

|

Polyurethane (PU) |

Quiet, floor-protective, chemical-resistant | Indoor industrial or warehouse use |

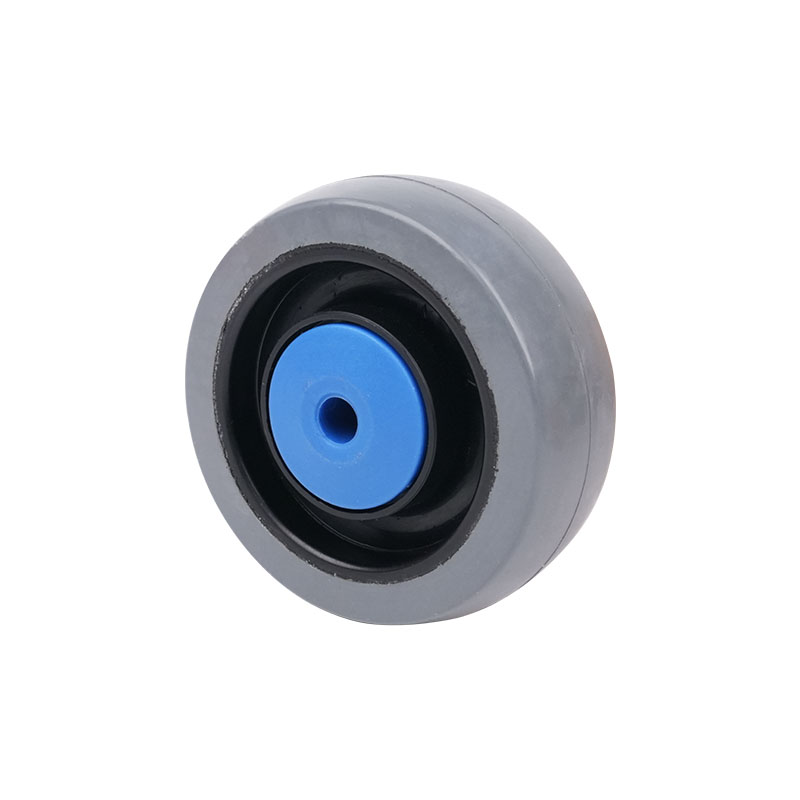

| Rubber / TPR (Thermoplastic Rubber) | Shock-absorbing, smooth, non-marking |

Hospitals, schools, clean environments |

|

Nylon / Polyolefin |

Lightweight, low rolling resistance, moisture-resistant | Food processing or wet areas |

| Cast Iron / Steel | High strength, handles extreme loads |

Factories, foundries, heavy-duty carts |

|

Phenolic / Resin |

Heat and chemical resistant |

Ovens, high-temperature conditions |

5. Key Selection Factors

Before choosing casters, evaluate these performance aspects:

- Load Capacity – Calculate total load ÷ number of casters, then add a 30% safety margin.

- Floor Type – Softer wheels for hard floors, harder wheels for smooth surfaces.

- Environment – Consider moisture, temperature, or chemical exposure.

- Mobility Needs – Swivel for maneuverability; rigid for straight-line travel.

- Mounting & Height – Ensure enough clearance for wheel diameter.

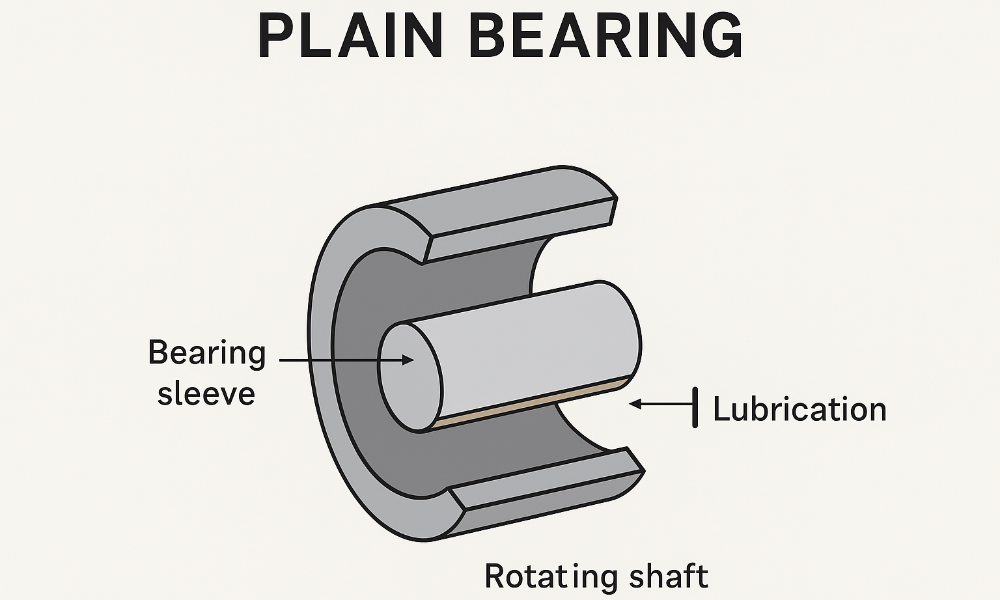

- Noise Level – Choose soft treads or precision bearings for quiet operation.

6. Quick Caster Matching Guide

Application |

Recommended Caster Type |

Suggested Wheel Material |

|

Heavy Machinery |

Rigid + Swivel Combo | Polyurethane or Steel |

| Medical Equipment | Swivel with Brake |

TPR or Rubber |

|

Warehouse Carts |

Swivel + Rigid | PU or Nylon |

| High Heat Area | Fixed |

Phenolic or Metal |

|

Food Industry |

Swivel |

Nylon or Stainless Steel |

7. Maintenance Tips

Keep wheels clean and free of debris.

Check bolts, nuts, and bearings regularly.

Lubricate swivel raceways and axles as needed.

Replace damaged wheels immediately to avoid equipment strain.

Conclusion

Choosing the right caster is more than just picking a wheel — it’s about understanding load, environment, and mobility needs. By knowing the types of casters and wheel materials, you can improve safety, extend service life, and ensure smooth movement for any equipment.

Get Your Custom Casters Today

Contact us today to get samples, catalogs, or a custom quote.

Email: [sales02@targetcasters.com]

WeChat/WhatsApp Support Available:+86 189 5830 8581