What Are Plain Bearings?

Introduction: What Are Plain Bearings?

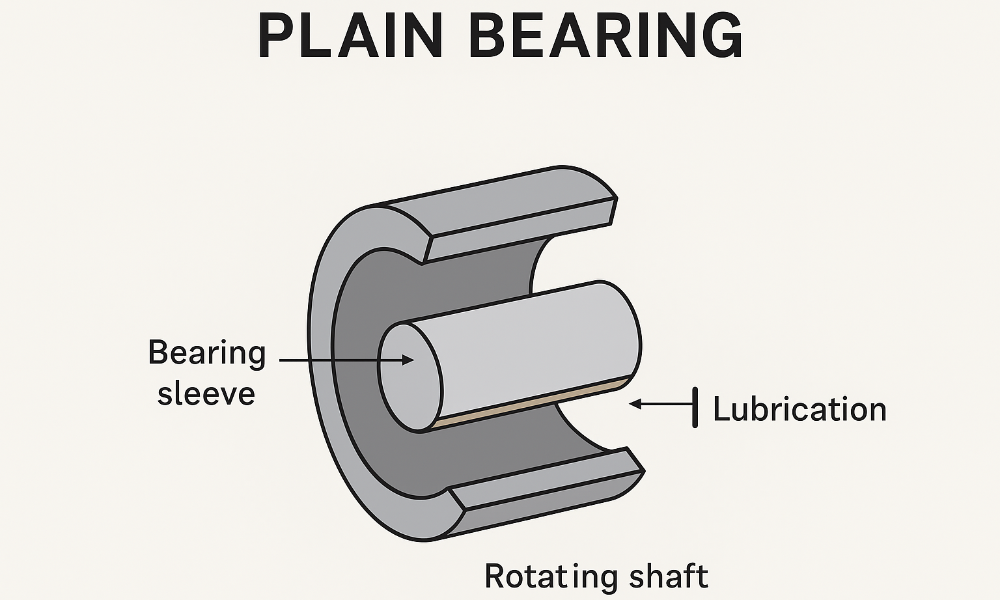

Plain bearings—also called sleeve bearings, journal bearings, or bushings—are essential components used to support rotary, oscillating, or linear motion. Unlike ball or roller bearings, plain bearings operate through sliding contact, providing smooth movement with a simple and compact design. They are widely used in industrial machinery, automotive systems, construction equipment, and many other applications where durability and load capacity are key.

Including plain bearings in your design can significantly improve reliability, reduce maintenance, and extend service life, especially in harsh environments.

How Do Plain Bearings Work?

Plain bearings function by creating a stable interface between a shaft and a housing. During motion, a lubrication film—oil, grease, or a self-lubricating material—reduces friction and wear. This allows the shaft to operate smoothly even under high load.

Main Types of Plain Bearings

To support different directions and forms of load, several types of plain bearings are used:

- Radial (Journal) Bearings – Support loads perpendicular to the shaft; ideal for rotating machinery.

- Thrust Bearings – Resist axial loads and are used where force acts parallel to the shaft.

- Linear Bearings – Provide straight-line motion with minimal friction.

These variations give engineers flexibility when designing compact, high-strength systems.

Popular Materials Used in Plain Bearings

Choosing the right material is critical for performance. Common options include:

- Metallic Bearings

Bronze, brass, and bi-metal structures deliver excellent strength and wear resistance.

- Sintered Bearings

Porous metals capable of absorbing lubricants, allowing continuous self-lubrication during operation.

- Polymer (Plastic) Bearings

Engineered plastics that incorporate solid lubricants deliver corrosion resistance, low friction, and often maintenance-free operation.

- Composite Bearings

Layered structures combining metals with PTFE or fiber reinforcements provide an ideal balance of strength, noise reduction, and low friction.

Key Advantages of Plain Bearings

When comparing plain bearings to rolling bearings, several benefits stand out:

1. High Load Capacity

Their wide contact surface allows them to handle heavy loads and shock impacts better than ball bearings.

2. Simple, Compact Design

With fewer parts, plain bearings are easier to install and ideal for applications where space-saving matters.

3. Superior Durability

They tolerate dirt, vibration, and challenging working conditions, extending system lifespan.

4. Cost-Effective Operation

Manufacturing costs are lower, and maintenance is minimal—especially with self-lubricating plain bearings.

5. Reduced Noise and Vibration

The sliding mechanism naturally dampens noise, making them perfect for low-noise equipment.

Limitations to Consider

Plain bearings provide excellent value but may not be ideal in every situation:

- Higher friction than rolling bearings at extreme speeds

- Require proper lubrication (unless self-lubricating)

- Precise shaft-to-bearing clearance is essential

- Understanding these factors ensures optimal performance and longevity.

Plain Bearings vs. Rolling Bearings: Which Is Better?

When selecting between the two, consider:

| Feature | Plain Bearings | Rolling Bearings |

| Load Capacity | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

| Shock Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Noise Level | ⭐⭐⭐⭐ | ⭐⭐⭐ |

| Cost | Low | Higher |

| Space Requirement | Very compact | Larger |

| Maintenance | Low (self-lube) | Regular lubrication |

Plain bearings shine in high-load, dirty, or impact-heavy applications, providing a durable and economical solution.

Common Applications of Plain Bearings

Plain bearings are used across many industries due to their versatility:

- Automotive: engine components, suspension systems, steering mechanisms

- Heavy Machinery: hydraulic pumps, conveyors, crushers

- Construction & Agriculture: loaders, excavators, tractors

- Energy Sector: wind turbines, hydro turbines, generators

- Automation & Robotics: precise, low-noise motion systems

Wherever reliability and long service life are required, plain bearings play a critical role.

Why Choose Our Plain Bearings?

We supply high-performance plain bearings designed for both standard and specialized applications:

- Custom materials and configurations

- Long-lasting, maintenance-free performance

- Excellent load capacity and environmental resistance

- Cost-effective solutions tailored to your project requirements

Whether upgrading existing equipment or developing new systems, our plain bearings deliver stable, consistent performance you can trust.

Conclusion

Plain bearings combine simplicity with exceptional reliability. With high load resistance, compact size, and long service life, they are essential components for modern machinery. If you’re designing an efficient, low-maintenance motion system, plain bearings could be the perfect solution.

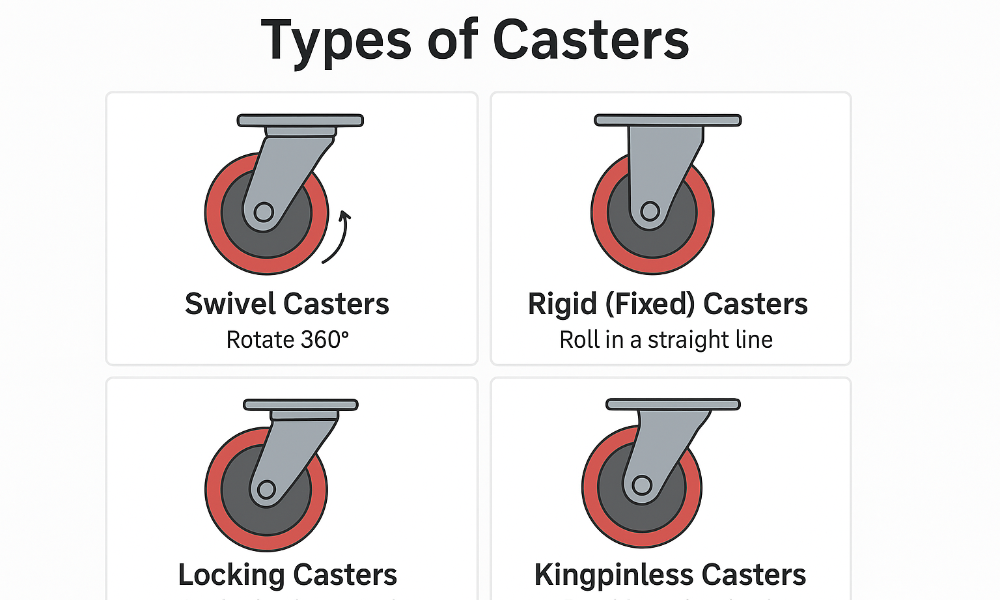

Get Your Custom Casters Today

Contact us today to get samples, catalogs, or a custom quote.

Email: [sales02@targetcasters.com]

WeChat/WhatsApp Support Available:+86 189 5830 8581